Iron Core Oil-immersed Shunt Reactors act as an absorber of reactive power in order to increase the energy efficiency of a power system.

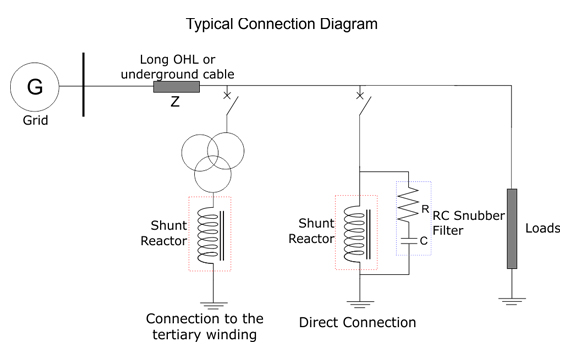

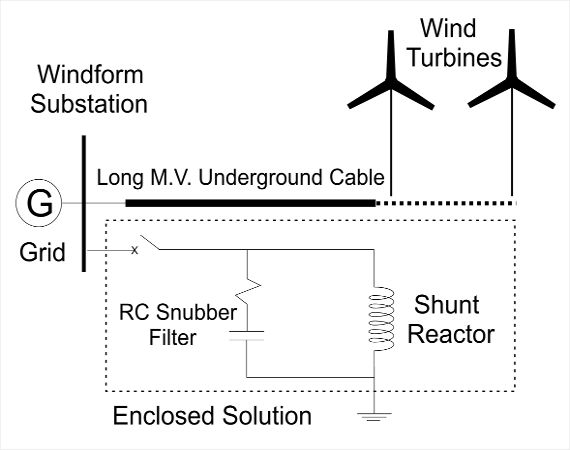

Shunt Reactors are used to compensate the capacitive reactive power that is generated by long and lightly loaded transmission lines, as well as underground cables. This allows the flow of more active power through the system while avoiding over-voltages. Shunt Reactors can be connected directly to the power line or tertiary windings of a three-winding power or distribution transformer.

The main windings and magnetic circuit are immersed in oil, which acts as a cooling medium. It can both absorb heat from the reactor windings as well as conduct the heat away through the oil.

The core of an oil-immersed reactor is made of ferromagnetic materials, with one or more built-in air gaps. These air-gapped iron cores are designed to withstand not only mechanical stress during normal operation but also fault conditions in the network.

In high power and high voltage systems, shunt reactors should be used with RC snubber filters due to the fact that in such systems, switching transient voltages are extremely high and the switching devices may get damaged without proper damping measures.

Advantages

- Iron core oil type construction

- Limited temperature rise enables longer lifetime

- Special surface protection against UV and pollution Class IV areas

- Low losses

- Low noise level

Typical Applications

Shunt reactors are mainly used for reactive power compensation of long or lightly loaded transmission lines as well as underground cables used in:

- Wind Farms

- Subways

- Urban Distribution Systems

- Industrial Zones

- University Campuses

- Substations

| Technical Specification | |

|---|---|

| Voltage | Up to 36 kV |

| Power | Up to 5 MVAr * |

| Type | Oil-immersed |

| Frequency | 50 Hz / 60 Hz |

| Winding | Aluminium or copper winding |

| Painting | RAL 7035 or other colors on demand |

| Temperature | -30°C to 55°C |

| Insulation class | A class or custom |

| Cooling | ONAN, ONAF |

| Standards | IEC 60076-6, IEEE Std. C57.21 |

| Options | - Taps - Enclosure - Complete solution with CBs, snubber circuit and protection relay - Thermometer - Oil level indicator - Silicagel - Other accessories on demand |

*Consult factory for higher values.