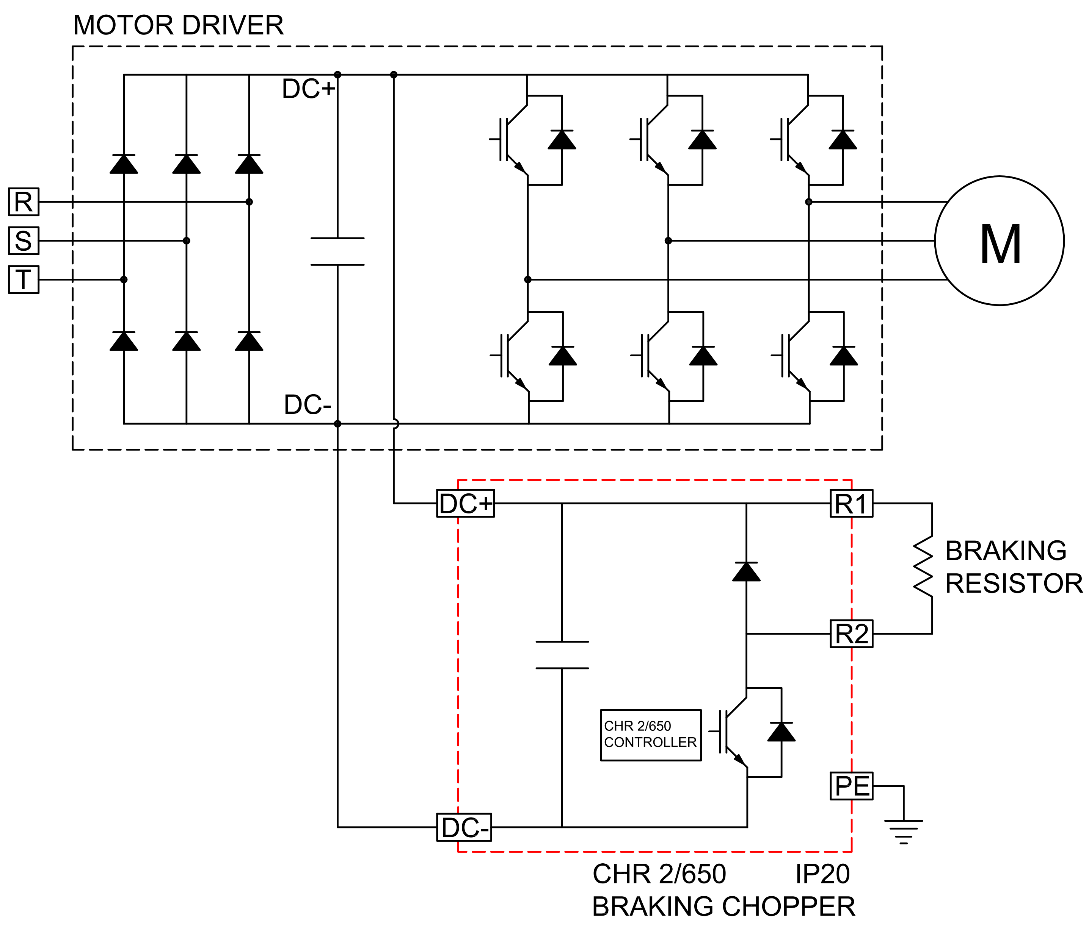

Braking chopper is used for limiting the DC link voltage of a frequency converter based motor drive. When an induction motor slows down, it acts as a generator and feeds energy back into the converter, and hence the dc link. The braking chopper transmits this braking energy of the drive to a resistor, to be dissipated as heat.

Typical applications of braking choppers are motor drives with high inertia loads such as trains, cranes, centrifuges, elevators, conveyors, large fans, etc.

Features

- Suitable for all brands of 3Φ motor drives

- Panel wall-mounted

- Easy installation

- Simple wiring

- Simple operation

- Maintenance free

- High reliability

- Smart digital control

- Self and Remote RESET functions

- Over-voltage protection (OV)

- Over-temperature protection (OT)

- Short-circuit protection (SC)

- Resistor thermal protection (RT)

- Led display for status and faults:

“RUN”, “OV”, “OT”, “SC”, “RT”

| Technical Specifications | |

|---|---|

| Input Voltage | 650 VDC * |

| Suitable Drive Voltage | 400 VAC |

| Suitable Drive Power | 2.2 - 100 kW |

| Rated Continuous Current | 40A |

| Rated Pulsed Current (ED=10 %) | 200 A |

| Rated Continuous Power | 26 kW |

| Rated Pulsed Power (ED=10 %) | 130 kW |

| Minimum resistance value | 3.1 Ohm |

| Ambient Conditions | -10 to 40⁰C *, max 1000m * altitude |

| Storage Temperature | -25 to 70⁰C |

| Dimensions (WxHxD) | 209,1mm x 293.4mm x 146,9mm |

| Weight | 4 kg |

| Protection Degree | IP 20, EN 60529 |

| Parallel Operation | Up to 7 modules, approximately 1000kW peak braking power |

* Input voltage can be between 200-900VDC.

** For higher values, please consult us.